| BALL TRANSFER TABLES This is an excellent way to easily rotate and position products manually at workstations or inspection areas. Ball transfer tables also provide a smooth transition from converging conveyor lines to other conveyors or system components. |

| GRAVITY FLOW RACKS Gravity rack systems have been proven to be the most economical and productive method of stocking, storing and retrieving merchandise in warehouses. Productivity and ease of operation are increased due to stocking done on one side of the rack, and product retrieval on the opposite using the (FIFO) first in- first out method. Picked product goes directly onto a conveyor system proving to be the most speedy and efficient way to service your customers and remain employee friendly at the same time. |

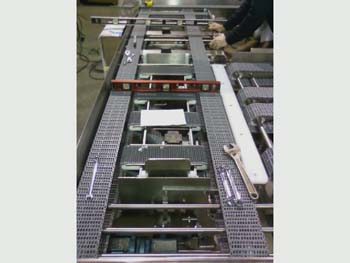

| CABLE DRIVE CONVEYORS Cable drive systems manufactured by ACS are engineered to be maintenance-free and exceptionally strong, yet take up minimal space. Driven by either AC or DC motors, depending on your needs, soft start units insure smooth acceleration and deceleration during start up and shut downs preventing can tipping and product damage. Double sheave drive units used in long configurations allow for positive traction eliminating cable slippage. |

| GRAVITY RODWORK FITTINGS A complete line rodwork gravity conveyor sections and related assemblies are designed for each customer’s particular application. Manufactured of stainless steel round rods or stainless steel half-rounds. Also, a unique system of quick-release clips allows a quick change over for conveying varying sized products. Twister designs can re-orient containers 90 or 180 degrees and drop-out gates discharge products to various desired locations. High density, anti-friction, noise reducing covers are also available. |

| DUAL V-BELT AND ROUND BELT CONVEYORS This conveyor is designed for the canning industry to receive cans discharged at a high speed from a bodymaker line and convey them horizontally to an elevator, unscrambler, or re-orienter. |

| MATT TOP CHAIN CONVEYORS Matt top chain conveyors are a wider width version of tabletop chain configurations. Widths of more than twelve inches are popular in the food and beverage industries because of ease of clean up and wash down duties. The minimal stretch properties and lowered mechanical maintenance necessary lowers overhead and overall operating costs. |

| TABLE TOP CHAIN CONVEYORS There are many styles to fit your specifications including chains made of thermoplastic, steel, and stainless steel. Available widths vary from one to twelve inches wide. Variable speed motors allow the customer to adjust linear speed to their specific needs. Options also include systems to provide for periodic maintenance wash downs, temperature extremes, accumulation areas, parallel transfers, and food handling approved materials. |

| ACCUMULATING CONVEYORS AND TABLES Choose from single direction or bi-directional capabilities with either minimal back pressure or zero pressure accumulation options to aid in protecting your products and profits. Custom designs include tables, verticals, merry-go-round cable ways and turntable styles to divert the product to single or separate lines. They are engineered to provide whatever back up time is necessary for your individual needs. |

| MAGNETIC CONVEYORS Custom designs by ACS offer limitless possibilities. Conveyors combines with magnetic elevators and lowervators in a camel back design have been proven to increase production and provide trouble-free operation with minimal maintenance and can be combines with gravity rodwork infeed to complimentary ferrous canning operation. |

| ROLLER CONVEYORS Available as either gravity or powered, American Conveyor can provide systems with roller sizes, bearings, and strength capabilities to match your specific needs. Powered conveyor systems can be chain, line shaft, or belt driven. Curves, inclines, and spurs combine to allow you to make the most of your factory space. |

| BELT CONVEYORS A complete range of belting materials including those approved for USDA/FDA applications. Both slider bed and roller bed styles are available. A variety of applications and material handling needs can be met with 45, 90, and 180-degree curves and varying inclines. |

| DEPALLETIZER A giant technological advancement for ACS, our depalletizer is the premier empty container handling system in the industry. Features include easier clean up under the machine, and expanded gap within the elevator, improved chipboard grippers, and a flexible discharge from the product bed. Many other components and controls have been enhanced for a user-friendly machine at a noteworthy price point. |

| SYSTEM CONTROLS An integral part of many material-handling operations, system controls such as sensors, bar code readers, and logistic control boards are just a sampling of the available components that can be engineered into your system to provide hassle- free operation of your quality American Conveyor Systems’ products. |

| METAL FABRICATION AND WELDING Our full capacity shop allows for production in either large or small quantities. A high standard for perfection and strict quality control ensures your end product not only performs as expected, but also has a superior visual appearance. |

- 215/943-9220 Fax:215/943-9282

- info@american-conveyor.com

- 1601 Harmer Street Levittown PA 19057